Cooling Tower PVC Drift Eliminator Manufacturer in Kolkata, West Bengal

Cooling Tower PVC Drift Eliminator Supplier in Kolkata, West Bengal

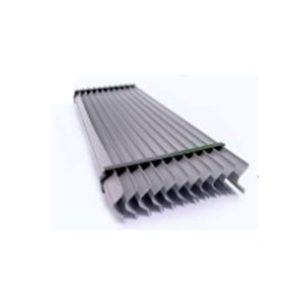

We are one of the eminent Cooling Tower PVC Drift Eliminator Manufacturer & Supplier in Kolkata, West Bengal, Bihar, Odisha, Jharkhand, Chattisgarh. Drift eliminators are used to capture water droplets in the air stream that otherwise would be lost to the atmosphere. Entrapping these droplets is important for not only conserving water as a resource but also to prevent cooling tower water from contaminating the area peripheral to the cooling tower.

The cooling tower industry uses drift rate to compare drift eliminator performance, a relationship that correlates droplet capture efficiency to the water circulation rate in a tower.

Supercool’s Drift Eliminators are specifically designed to achieve maximum drift removal efficiency in both crossflow and counterflow tower applications with various product options available to minimize pressure drop, drift loss, cost, or a combination of all three.

In each and every cooling tower, there is an amount of evaporative water loss to the environment. Drift eliminators are designed to minimize how much water is actually carried out of the tower with the exhaust air. Simply put, keeping water droplets from exiting the tower is a drift eliminators’ main responsibility

Effective and efficient drift eliminators will remove these water droplets from the air and minimize the loss of processed water within the tower. This cooling tower part can swiftly change the direction of the water droplets in the air. If working effectively, the water will then be separated from the air. This eventually leads to the droplets being pulled back into the tower. The amount of circulating water is then limited from the cooling tower’s exhaust. There is no doubt that these drift eliminators serve a crucial purpose within the cooling tower. Create a sudden change of direction in air stream. Separate droplets from the air. Deposit these drops on the eliminator surface. Droplets drain back into the tower.

Different Type of Drift Eliminators

- Crossflow Drift eliminators: These feature horizontal air flow while water flows in the same direction, downward. The advantages of a crossflow model are that it produces minimal noise, consistently performs at a high level and requires little to no general maintenance.

- Counterflow Drift eliminators: This sends air flow vertically instead of horizontally. Water actually flows from the top all the way to bottom with this design, though. This flow allows the water to exhaust quicker. As is the case with crossflow, there are many benefits of the counterflow drift eliminators. A low amount of energy is consumed within these models. Maintenance is again minimal, and this features a lower pumphead.

- Standard drift eliminators: These eliminators are tasked with the duty of preventing harmful water droplets from escaping into the environment. (pictured furthest to the left)

- Cellular drift eliminators: Designed for maximum drift removal efficiency. The cellular design allows for a lot more flexibility for installations. (pictured furthest to the right)

- Blade Drift eliminators: This is a cost-effective option known for its long lifespan and durability.

Advantages of Use

- Minimal noise.

- Cost-effective.

- Low maintenance required.

- High performance.

- Consumed energy is optimized

- Materials Used in Drift Eliminators

There are only few drift eliminator materials used by manufacturers today. However, this makes options easier, which does not necessarily skimp on quality since they are also designed to serve their purposes best.

- Polypropylene (PP) – a recyclable material that is both plastic and fiber, polypropylene can tolerate heat better than PVC. PP is also resistant against moisture but is susceptible to degradation when constantly exposed to UV.

- Polyvinyl Chloride (PVC) – the most commonly used and also the lowest in cost, PVC drift eliminators are resistant from corrosion. However, PVC is also known to have toxic byproducts.

- Metal – with its more robust nature, steel drift eliminators are ideal for use in higher temperatures and container shipments. However, metal is prone to corrosion, but can be reinforced with a coating for protection.

The Ideal Features of Drift Eliminators:

- Finally, when choosing from your narrowed down options, make sure that the model meets most, if not all of the following features:

- Certified and compliant with safety regulations.

- Can maintain total drift loss by at least .001%.

- High performance.

- Cost efficient.

- Adjustable and flexible for conversion.

- Seamless in process

- Easy to use and inspect for maintenance issues.