Cooling Tower S.S. 304 Grids Supplier in Kolkata, West Bengal

Cooling Tower S.S. 304 Grids Manufacturer in Kolkata, West Bengal

We are one of the renowned Cooling Tower S.S. 304 Grids Supplier & Manufacturer in Kolkata, West Bengal, Bihar, Odisha, Jharkhand, Chattisgarh. Owing to our rich industry experience, we are offering Cooling Tower S.S. 304 Grid to our clients. Experts in production phase have basically relied on Cooling Tower Grid and finished this product in excellent manner. Offered range is widely used and is offered at feasible price.

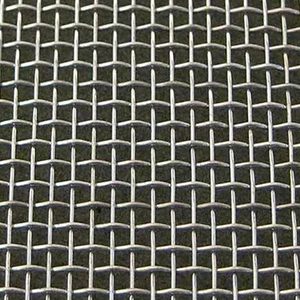

Fill support S.S. 304 Grids are made in stainless steel wire. It is designed to keep fill splash bars horizontal and also to take load of water as well as fill during operation. It is available for treated timber splash bars or PVC rectangular splash bars, PVC V type splash bars fills.

The grid is used in cooling towers as tower packing. It is structured inside for the cooling tower as a bed for providing optimum space for cooling air to flow upwards to carry away the heat from the water. The purpose of the grid is to splash fill which is of maximizing the number of water droplets in any unit volume of water, and minimizing the size of those droplets in order to produce the highest surface area of water available to the passing air.

The configuration of the grid allows water droplets to fall across multiple layers of horizontal strips. Even as the water droplets bounce off from one layer to another the thin strips exert shearing action on them causing them to break into smaller droplets. This results in a far more efficient working of the splashing principle.

The grids are supported in uniformly spaced tiers throughout the cell width and length on stainless steel wires hung from supports installed under the water distribution system using spider shaped clips. Polypropylene supports are also provided and they are specifically designed to secure the grid to the wires. Each grid in each tier is secured to all adjacent grids by special clips that tie the entire fill assembly securely in place.

The UV inhibited polypropylene is resistant to attack from acids, alkalis, hydrocarbons and biological and chemical attack.