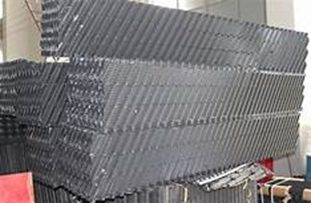

PVC Fill Block Manufacturer in Kolkata, West Bengal

PVC Fill Block Supplier in Kolkata, West Bengal

We are one of the leading Cooling Tower PVC Fill Block Manufacturers & Suppliers in Kolkata, West Bengal Bihar, Odisha, Jharkhand, Chattisgarh of premium quality . The offered product is developed with the help of top quality material and modular techniques in compliance with set industry standards. This product is made obtainable in number of specifications for our customers to choose from. Clients can avail this product from us at nominal price in a stipulated time.

Supercool is offering a wide range of Virgin PVC Fill Block for Cooling Towers , manufactured using quality material. These Fills are designed to meet the specific cooling requirements of most cooling Towers . In these fills, the crossing of air and water stream is in close proximity and thus develops a diffused turbulence, leading to evaporation and efficient heat transfer. Our range of PVC fill Block are widely appreciated by our clients for longer functionality and is specially treated to cover maximum area for heat exchange.

Banking on our enriched industry experience, we are engaged in offering a huge gamut of PVC Fill Block. Our standard fill is constructed of a honeycombed PVC film. This honeycomb construction ensures even water distribution and high-efficiency water to air heat transfer. The PVC fill Block shall withstand a maximum inlet water temperature of 55°C. We can supply HIPS and ABS fills for high-temperature application up to 100°C.

These PVC Fill Blocks can also be cut to length to customer’s specific requirements, or supplied as loose sheets.

Counter Flow Cooling Tower Fill improve water distribution by splitting the water stream as it descends through the fill pack. PVC Fill Block splits the water stream 8 times in a 12” (305 mm) vertical path. High thermal performance (high KaV/L) and low pressure drop are simultaneously achieved through engineered flute/microstructure design and the highest manufacturing standards.

PVC Fill Block

- The most widely used type material

- Fire Classification: M2 with 42% Oxygen Index

- Color: Black, green, blue, transparent or other

- The most important disadvantage of material is low temperature resistance. The deformation which starts by changing the PVC material form over 45 degrees causes the surface to become completely unusable by crumpling at higher temperatures.

PP Cooling Tower Fill Block

- High-temp resistant type material

- Working Temperature: Max. 90 °C

- Color: Black, green, blue, transparent or other

- The durability to heat is quite high.

- It protects the chemical structure and form at high temperatures.

- Acidic and basic strengths such as CTP (glass fiber reinforced polyester) are high.

- They do not show any corrosion, melting or decay, they do not give the color, odor and taste of the liquid they are in contact with.

- Their flexibility is sufficient.

- They can form smooth surfaces in molds.

- No parasitic effects, which is a very important feature in water cooling towers

- The coefficient of friction is low.

CPVC Cooling Tower Fill Block

Some of cooling tower fill materials are made of high-temp resistant CPVC. They are hot pressed in the certain mold, and then produced according to different design to be used in different cooling towers, especially in industrial cooling tower. Today, the most commonly used film fill sheet material is rigid PVC. It is durable, provides a long service life, is excellent for wetting (conditioned to allow surfaces to be covered completely by water), is self-extinguishing and can be formed into many shapes

- Splash Fill Block : Splash fill consists of layers of horizontal bars or slats. When the warm water hits the surface of these bars, it spreads, breaks, and forms small droplets. As more droplets are formed, the contact between air and water flow is increased, which as a result accelerates the rate of cooling and evaporation.

Splash fill media were traditionally made from wood, but modern cooling tower fill material is made from PVC. PVC is more efficient as it facilitates better heat transfer. A big advantage of splash fill is that it’s very forgiving of insufficient initial water distribution, since the splashing activity redistributes the water at each level of splash bars. Because of this, a cooling tower with splash fill effectively handles water containing debris. Maintenance is also easier, because its open nature offers easy visual inspection of the water flow pattern and the condition of the fill.

- Film Fill Block: Film fill provides sheets of material that are shaped into a corrugated pattern for the water to travel across. It can be combined and stacked into blocks, to create various thicknesses and heights to fit individual cooling towers. Despite the advantage of splash fill in water distribution, film fill is by far the more popular type of fill, mainly due to its ability to expose greater water surface within a given packed volume.

Cooling tower Fill Block makes hot water have much more surface area with sheet and air and the medium of tremendously extended film fill so that the hot water is cooled quickly. After being cooled, the water flows in a water container from which it is pumped again to repeat this cycle.

The waste heat produced in industrial production or refrigeration process is generally driven away by cooling water. The Cooling Tower functions as heat exchanger between the cooling water carrying waste heat and the air in the tower.

Fill, or wet deck or surface, is a medium used in cooling towers to increase the surface area of the tower. This enlarged surface area allows for utmost contact between the air and the water flow, which as a result allowing greater evaporation rates. Cooling tower fill is made of PVC or PP plain plate by specialized machine.